Artisane 3

Not only does it have the same features as the Artisane 2, the Artisane 3 also comes with:

- A programming screen with 6 integrated, editable programs to automatically adjust rolling, elongation, rotation speed, disconnection of the rear conveyor belt and the option of tapered ends.

- Tapered ends: a rear conveyor belt with adjustable geometry. This feature makes it possible for an artisan to adjust the finish of the bread or baguette ends etc., by honing them to a lesser or greater extent until they become tapered.

The solid frame consists of two thick machined and braced aluminium sides (10 mm)

Drive is belt and chain driven

The unique design of the conveyor belt housing makes it possible to quickly replace the front and rear liners

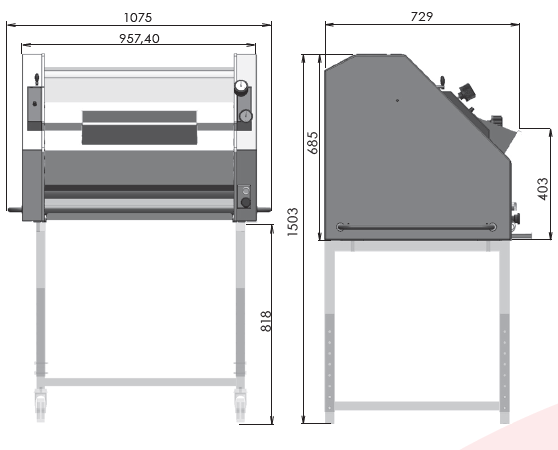

Characteristics

- The side housings are painted steel.

- The 3 laminating rollers are non-stick.

- Carrying handles included.

- Variable speed can be adjusted using the potentiometer on the front panel. It can be adjusted from 0 to 1500 pieces/h.

- The rear conveyor belt can be disconnected. This function gives the appearance of manual shaping. This system is ideal for very hydrated dough.

- By adjusting both the speed and the operation of the rear conveyor belt, the user can make the machine compatible with all types of dough.

- 220V Singe-phase – 0.75Kw – 2.2A – 200Kg net – Packaging (LxWxH) 1050x830x840 – 230Kg